Role of heat exchangers in hydronic systems is crucial for efficient heat transfer within buildings. These components play a significant part in transferring heat from a fluid to another without the fluids coming into direct contact. This blog post will research into the importance of heat exchangers in hydronic systems, their functionality, types, and benefits they offer in maintaining optimal temperatures and energy efficiency in residential and commercial spaces. Understanding the role of heat exchangers is key to maximizing the performance of hydronic heating and cooling systems.

The Functionality of Heat Exchangers

Basic Principles of Heat Exchange

Your understanding of heat exchangers is crucial to grasp their role in hydronic systems. Heat exchangers are vital components that facilitate the transfer of thermal energy between two or more fluids at different temperatures. This exchange occurs without the fluids coming into direct contact with each other, preventing contamination.

Types of Heat Exchangers Used in Hydronic Systems

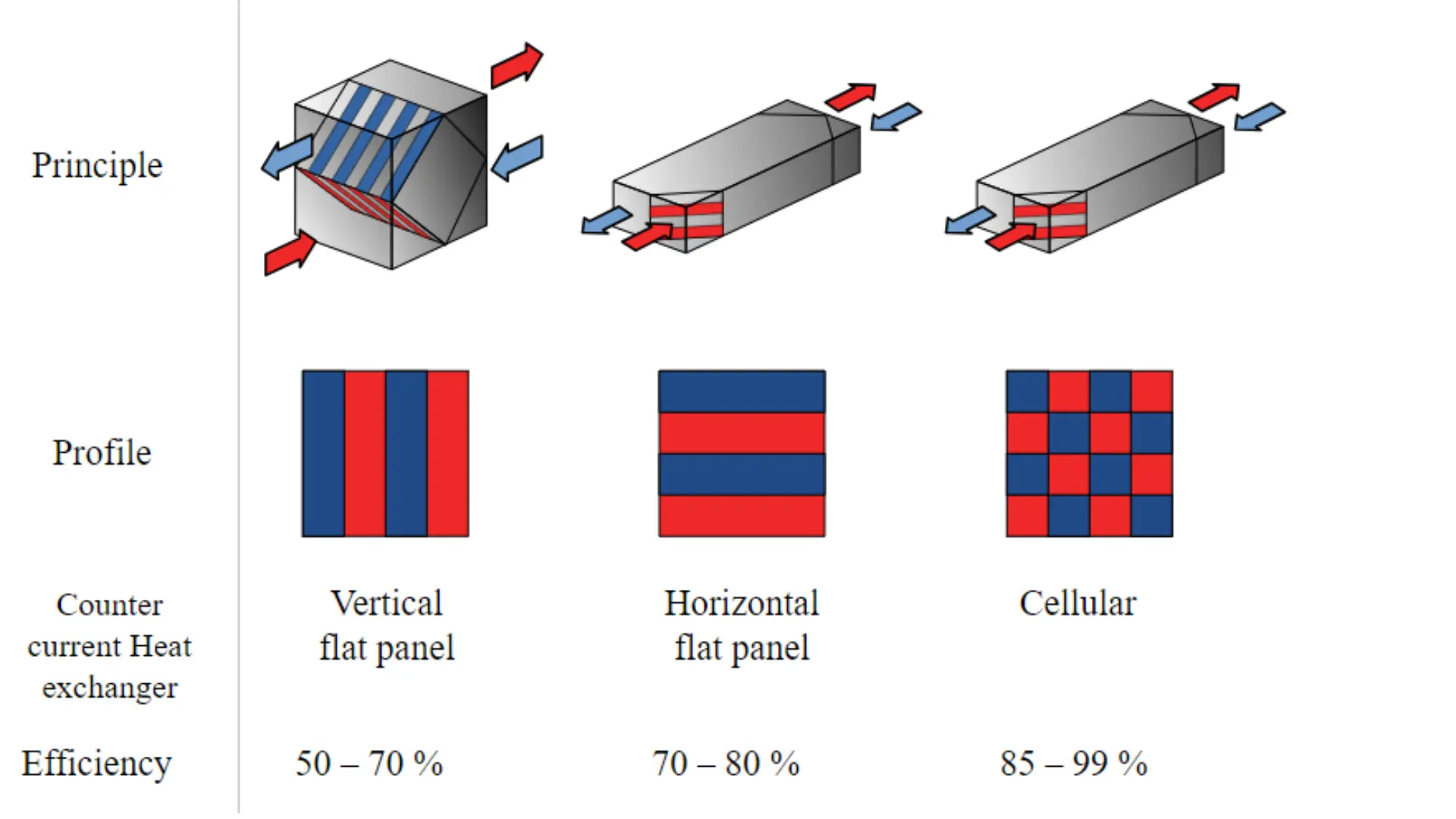

Exchangers play a pivotal role in hydronic systems by enabling the efficient transfer of heat. There are various types of heat exchangers that are commonly used in these systems, each with its own unique design and functionality. Understanding the different types can help in selecting the most suitable option for specific system requirements.

| An Overview of Heat Exchangers | Description |

|---|---|

| Shell and Tube | One of the most common types, consisting of a shell with multiple tubes inside for fluid exchange. |

| Plate Heat Exchanger | Utilizes metal plates to transfer heat between fluids, offering high thermal efficiency in a compact design. |

| Brazed Plate | Compact and efficient, with corrugated plates brazed together to form the heat exchanger. |

| Shell and Coil | Consists of a coiled tube within a shell, allowing for efficient heat transfer in a compact space. |

| Plate and Shell | Combines the benefits of plate and shell heat exchangers for enhanced heat transfer performance. |

Perceiving the distinctions between these types can aid in making informed decisions for optimal performance in hydronic systems.

Integration of Heat Exchangers into Hydronic Systems

System Configuration and Design Considerations

The integration of heat exchangers into hydronic systems plays a critical role in maximizing energy efficiency. The design and configuration of the system are key factors that determine the overall performance of the heat exchanger. Proper sizing, flow rates, and location within the system are imperative considerations to ensure optimal heat transfer and system functionality.

Optimization of Heat Transfer Efficiency

Systems must be designed to optimize heat transfer efficiency in order to achieve the desired level of performance. Factors such as material selection, surface area, and fluid flow patterns all play a crucial role in maximizing heat transfer within the system. By carefully considering these factors during the design phase, engineers can improve energy efficiency and reduce operational costs.

A well-designed heat exchanger system can significantly enhance the overall performance of a hydronic system. By integrating heat exchangers strategically and optimizing heat transfer efficiency, engineers can create systems that are more sustainable, cost-effective, and environmentally friendly.

Maintenance and Troubleshooting

Routine Heat Exchanger Maintenance

One crucial aspect of ensuring the optimal performance of heat exchangers in hydronic systems is regular maintenance. This includes inspecting for any leaks, cleaning the surface of the exchanger to remove any buildup or debris, and checking for signs of corrosion. By conducting routine maintenance, you can extend the lifespan of the heat exchanger and prevent potential issues from arising.

Common Issues and Troubleshooting Strategies

Troubleshooting common issues with heat exchangers in hydronic systems is important for maintaining efficiency. Some common problems include reduced heat transfer efficiency, leaks, and strange noises. To address these issues, start by checking the system for any blockages, ensuring proper water flow, and inspecting the exchanger for any damage. Additionally, make sure to bleed air from the system to prevent airlocks that can impede proper operation.

Innovations and Future Trends

Advances in Heat Exchanger Technology

Technology in heat exchangers has seen significant advancements in recent years, leading to improved efficiency and performance in hydronic systems. Engineers and manufacturers have been focusing on enhancing heat transfer capabilities, reducing pressure drops, and increasing corrosion resistance. Innovations such as compact designs, advanced materials, and improved geometries have revolutionized heat exchanger technology, making them more reliable and effective in various applications.

Future Prospects for Hydronic Systems

An exciting future lies ahead for hydronic systems, with a strong emphasis on energy efficiency, sustainability, and smart technology integration. The integration of hydronic systems with renewable energy sources such as solar and geothermal energy is gaining traction. For instance, the use of smart controls and IoT (Internet of Things) technology allows for better monitoring and optimization of hydronic systems, resulting in lower energy consumption and operating costs. As the industry continues to evolve, we can expect to see more innovative solutions that cater to the growing demand for sustainable and efficient heating and cooling systems.

Summing up Heat Exchangers In Hydronic Systems

On the whole, understanding the role of heat exchangers in hydronic systems is crucial for ensuring efficient heating and cooling processes in residential and commercial buildings. These components play a vital role in transferring heat between different fluid streams, helping to maintain optimal temperatures throughout the space. By recognizing the importance of heat exchangers and how they function within hydronic systems, building owners and HVAC professionals can make informed decisions to improve the overall performance and energy efficiency of the system.